Silicone materials have long been a dominant force in the request, with a wide range of operations in diligence similar to automotive, construction, healthcare, and electronics. Despite the emergence of colorful new materials and technologies, silicone continues to maintain its applicability and enthrall a significant share of the request. In this composition, we will claw into the reasons why silicone materials have been suitable to maintain their position and remain a go-to choice for colorful operations.

Silicone materials have a variety of applications in different industries, because of their endurance. Silicone is known for its unique properties, high-temperature resistance, biocompatibility, and excellent electrical insulation. These features are ideal for applications requiring durability, reliability, and high performance. According to Markets and Markets reports, the global silicone market is expected to reach $19.3 billion by 2025 and grow at a CAGR of 4.8% during the forecast period. The report says this growth is due to the increase in the demand for silicone materials for various applications, including automotive, medical care, and construction.

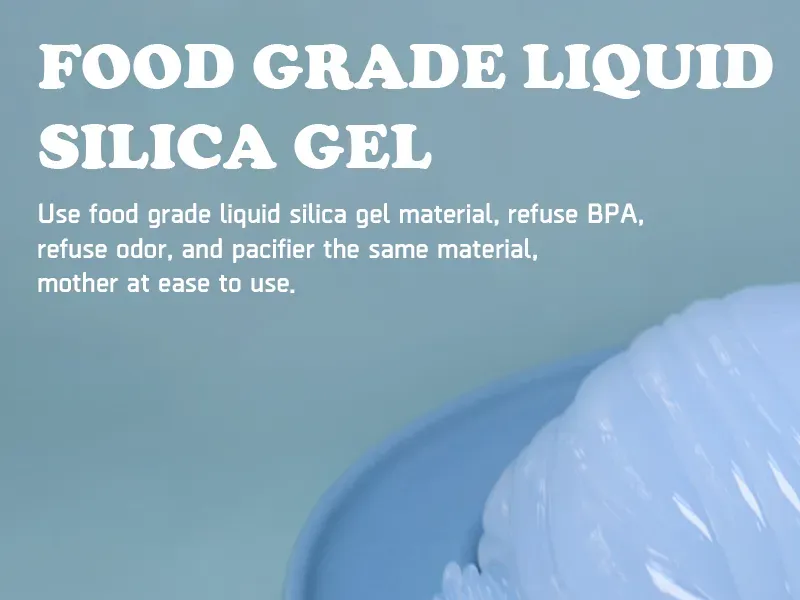

Especially in the healthcare industry, silicone materials have a long history of use. Its main contributions are found in devices and medical implants. According to the Journal of Biomedical Materials Research Part B: Authors in a study published in the Journal of Applied Biomaterials, "Silicone has been used to make medical devices for more than 50 years and is a well-established biomaterial for implantable devices. "The reason silicone is the material of choice for medical applications such as contact lenses, pacemaker leads, and breast implants is due to silicone's inertness, low toxicity, and biocompatibility.

Moreover, silicone has a wide application in the automotive industry and plays an important role in the enhancement of vehicle performance and safety. Silicone has essentially captured the market share for hoses, wires, gaskets, and seals because of its excellent durability and temperature resistance. ResearchandMarkets estimate that the global automotive silicone market will reach US$4.2 billion by 2025, with a CAGR of 5.0%between 2020 and 2025. The automotive silicone market is growing along with the industry's growing demand for lightweight and high-performance materials.

Additionally, silicone materials have unique optical properties that are ideal for electronic and optical applications. In a paper published in the journal Science, the author states that "silicones are interesting materials for optical applications because of their high transparency, low absorption coefficient, and low refractive index in the visible and infrared regions." The authors further pointed out that the incorporation of organic dyes or quantum dots into the silicone matrix can facilitate the development of new high-efficiency optoelectronic materials. This demonstrates how silicone materials can be used to develop innovative technologies and products that meet the changing needs of various industries.

Silicones are known to withstand extreme conditions such as high temperatures, UV radiation and harsh chemicals. The durability and longevity of the silicone material also contributes to its durability in the market. They also exhibit excellent resistance to aging and degradation, ensuring their longevity and reliability. According to a report by Grand View Research, the global silicone elastomers market size is expected to reach USD 10.8 billion by 2027, growing at a CAGR of 6.2% during the forecast period. The report attributes this growth to the increasing demand for durable materials in various applications such as construction, automotive, electrical and electronics.

In summary, the durability, unique properties, and versatility of silicone materials almost perfectly meet the changing needs of various industries including electronics, automotive, and healthcare, solidifying their position as the material of choice for high-performance that has long dominated the market. In addition, silicone technology is still being innovated and developed. In the future, we will definitely see more applications and products serving human beings.

Despite the advent of new materials and technologies, silicone materials are still relevant and demanded in highly competitive markets. Therefore, it’s certainly to say that silicone materials will continue to hold a significant share of the market in the coming years.

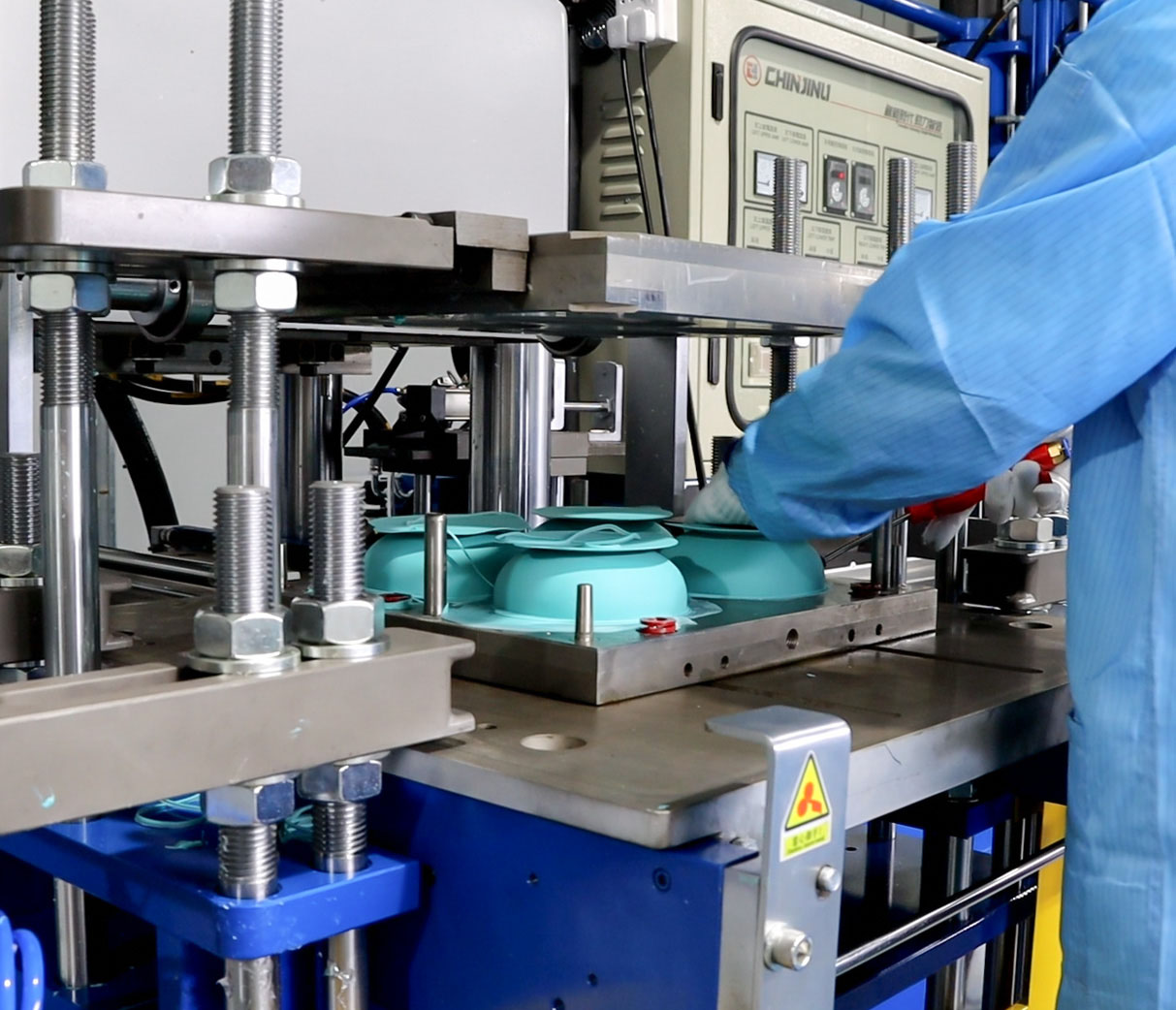

Newtop seized the opportunity, recruited troops, and established its own silicone company and factory in China. Now Newtop is already a top supplier of customized silicone products with more than ten years of production experience in China. Newtop has made outstanding achievements in daily chemical, mother and baby and pet industries, as well as electronics, automobile and medical industries. Therefore, choosing Newtop must be the first step for you to successfully enter the silicone industry. No matter you have any inspiration related to silicone, please leave your email address and send us an email, we will contact you as soon as possible and discuss your great cause together.