> Strong technical team

> High tech unique production lines

> Excellent design level

> High-efficiency intelligent equipment

> In-house tooling for fast turnaround

> Advanced cutting equipment

The Techniques Newtop Rubber proceed with:

The Liquid Injection Molding(LIM)

Below are the primary steps involved in the liquid silicone rubber injection molding process:

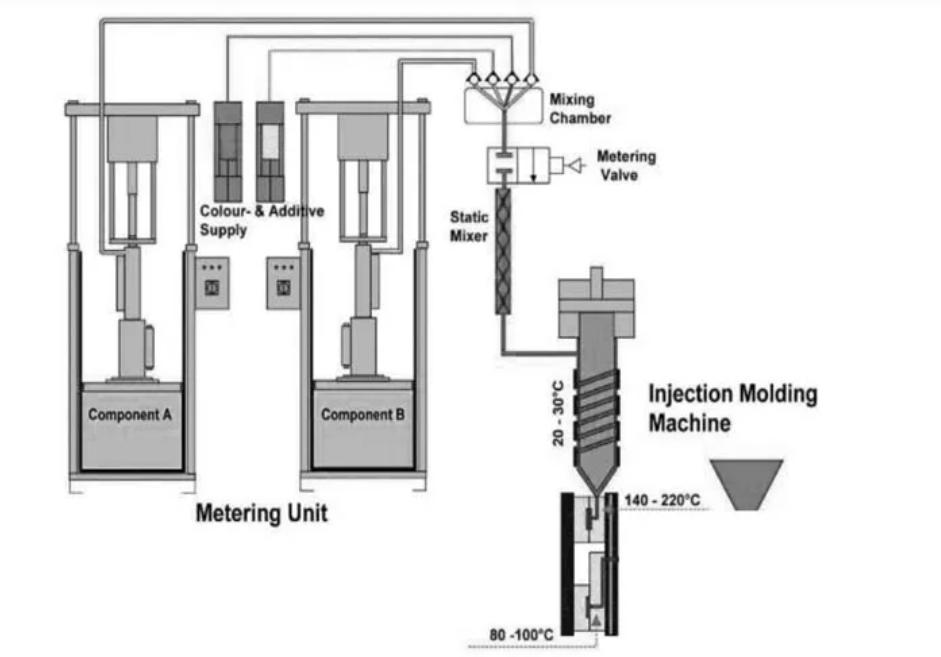

> The uncured liquid silicone starts in two containers, Compound A and Compound B, which connects to the pumping system. Barrel A holds the base-forming material, and Barrel B contains a catalyst. A metering unit automatically releases the two substances at a constant one-to-one ratio, as well as any pigmentation additive.

> The molder can program and customize the automated injection-molding machine and have the injection setting deliver the appropriate shot size for each job. The platens and pistons, which align and close the mold, have settings for the temperature, pressure, injection rate, and cycle time-adjusted in accordance with the customer's specifications

> After the completion of the setup, the molding machine heats the mold to the appropriate temperature and applies the appropriate clamping force. The mold closes in coordination with the machine's injector, pump, and supply. The injection mechanism then pushes the material into the mold and cavities.

> A combination of heat and pressure applied to the liquid silicone rubber cures the material until it solidifies. Upon completion of the cycle, the mold opens, and the part and flashing can be removed automatically or by a worker. Then, the mold closes and repeats the process.

> After the removal of the item from the mold, the post-molding process may include de-flashing, post-curing, inspection, and packaging.

Liquid silicone rubber overmold injection molding process involves two steps:

> A completed plastic or metal entity is placed into the mold site of an LSR mold, after which the LSR is overmolded directly onto the part.

> One of the benefits of liquid silicone overmolded parts and components is that the manufacturing process allows for the use of a non-plastic substrate, such as steel.

It is important to note that overmolding is the only way to incorporate materials, aside from other thermoplastics and LSRs, into the injection molding process.

MULTI-SHOT Injection Molding

Multi-shot injection molding, also known as two-shot molding, is a process where multiple materials are injected into the mold simultaneously. This differs from traditional techniques that involve only a single injection. Multi-shot molding is an enhanced version of the two-shot process, as it enables the combination of multiple materials into one production cell.

Multi-injection molding offers numerous functional and aesthetic benefits. For one, product designers have greater flexibility to create more innovative products, which is advantageous for users that require customization. Manufacturers and designers can easily incorporate multiple colors, combine otherwise incompatible materials and apply softer materials over hard surfaces.

Package Service with Added Value

We can help your products to be unique in your market.

How can we help you with our packaging service.

> Multiple packaging types. We have indented carton, OPP, PP box, ivory box, gift box and blister box.

> We will custom pack your product according to your requirements.

>Ship directly to end users, retail stores and distributors at home and abroad.