Every product has material requirements, but the medical industry is particularly stringent. When medical products and devices do not work as they should, the consequences can be serious, immediate and costly. Strict regulations on medical products help prevent these problems, but they also present a host of developmental challenges in bringing products to market. As demand continues to grow, Liquid Silicone Rubber(LSR) stands out from the competition.

One of the major hurdles faced by medical products is contact with living tissue, either externally (skin contact) or internally (e.g., implanted devices). It's a two-way challenge: the product must not irritate or otherwise affect tissue, and the material itself must not be adversely affected by contact with tissue.

Another requirement is sterilization. Whether designed for single-use or repeated use, medical products must be sterile, which often requires exposure to high temperatures. Many thermoplastics are not inherently resistant to heat.

Cleaning and disinfection may require the use of chemicals, so depending on the application, the material may also have to withstand the harsh chemicals to which it is regularly exposed. Some applications may expose the material to UV radiation, which can cause the material to break down or discolor, while other applications may expose the product to extreme cold, which can make the material brittle and prone to breakage.

Finally, there are cosmetic considerations. A product or device may perform flawlessly, but if it looks old, worn, or otherwise damaged, it may raise questions about its functionality.

For all these reasons, LSR can be an ideal material for medical applications. Almost every grade of LSR is biocompatible, and there are grades of the material developed and approved specifically for implants* and similar medical applications. LSR is very stable and can withstand high heat and exposure to cleaning and sanitizing chemicals. Its heat resistance also makes it suitable for heat-related therapeutic applications such as cautery, where it can be used as a safety shield for cautery tools.

On the flip side of extreme temperatures, the material is also suitable for applications that expose it to cold environments -- such as freezing warts and similar procedures. Unlike other materials that are flexible at room temperature, LSR does not become brittle in cold conditions. (Of course, LSR is not the only flexible material that can be used in medical applications. Thermoplastic elastomers, or TPEs, are less expensive and may be well suited for room temperature applications.)

Another reason why LSR components may be used on medical devices is purely for aesthetics. In the medical world, perceived quality can be crucial, and anything that appears to be a defect can be interpreted as an actual defect, even if it has no effect on function. For example, a transparent part that turns yellow due to exposure to UV light may continue to function normally, but this discoloration may be misinterpreted by patients and doctors alike. This is another area where LSR excels, being virtually independent of environmental factors. It is also highly scratch-resistant, so in addition to wearing away and maintaining its functionality, the LSR remains aesthetically pleasing throughout its lifetime.

In addition to meeting the stringent requirements of medical applications, LSRs have several unique and useful properties:

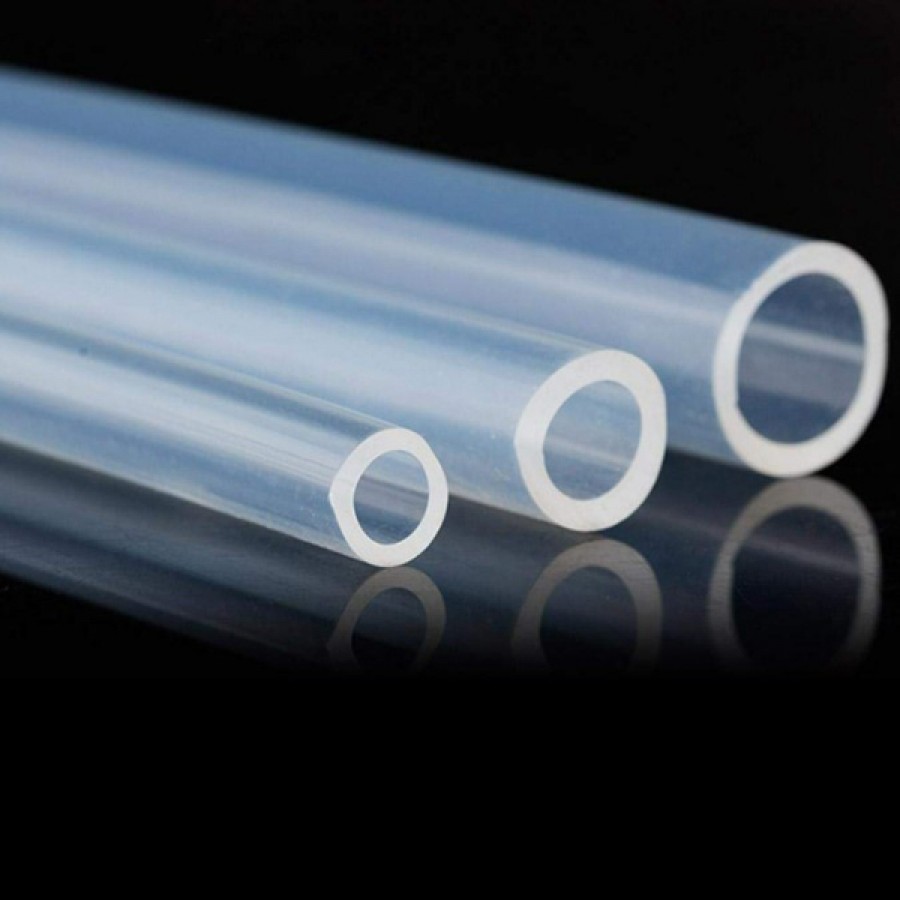

In the liquid state, LSR has a very low viscosity before being cured by heat in the mold. This enables it to fill very small features and thin walls without creating voids or porosity.

Transparent optical LSR is a new class of material available to developers. It is ideal for applications such as lamp shades, lenses and light pipes. It transmits light better than other plastics and second only to glass; its stability prevents damage from heat generated by light sources.

Because of its flexibility, LSR can be molded into shapes that would otherwise be trapped in the mold. LSR parts with undercuts, no draft, or even negative draft can be manually stripped from the mold without damage. This can eliminate the need for costly side-action cams and gives designers great flexibility.

LSR is available in a variety of durometers (hardnesses), allowing designers to match the material to the function of the part. Soft, relatively sticky LSR can be used as feet or bases for devices to prevent them from sliding while in use.

LSR molding is now affordable, as low as 25 pieces for prototyping, low-volume production, or bridge tooling.

LSR is also ideal for overmolding, where a molded or assembled part is inserted into another mold and then injected with LSR to form a second layer of material on top of the first. Overmolding is ideal for devices with handles.

In short, LSR is an ideal material for a variety of medical applications. While soft thermoplastics like TPE replicate some of its properties, no other material offers LSR's combination of biocompatibility; heat, cold, chemical, and UV resistance; durability; design flexibility; and molding sex. For some (but not all) applications final manufacturing will require facilities with medical ISO 13485 certification. Non-certified facilities can be used to produce components that do not require certification, and to develop and validate components that do require certification—form, fit, and function testing.

Industry Trends and Prospects

The LSR market has experienced continuous growth and expansion in recent years, and this trend is expected to continue in the next 5-10 years. Some sources predict that the value of the global LSR market will grow at a rate of 7.1%, from $2.4 billion in 2020 to $4.2 billion in 2028. The healthcare industry is one of the major drivers for the growth in LSR demand globally, as the medical manufacturing industry is experiencing significant growth.

It should be noted that, like most industries, the COVID-19 pandemic has disrupted the global LSR supply chain. However, the supply chain has begun to fully recover and will not affect the short-term or long-term demand for liquid silicone rubber in the medical manufacturing industry.

One trend that has surfaced is closer collaboration between product design and development teams and LSR injection molding machines. Newtop has found that this will help ensure products are designed for optimal manufacturability, minimizing rework and helping speed time to market. Alternatively, LSR can be formed using horizontal and vertical press applications, preferably in a Class 100,000 clean room.

Newtop added equipment and a clean room to produce precision moldings and ensured that operators were fully trained. In order to facilitate the customer's assessment of our capabilities, Newtop can present production certificates, previous experience, expertise and equipment, including permission to visit the factory.

The Future of Lsr as A Medical Material

As the demand for home healthcare and disposable devices grows, the demand for LSR's use in these products will also increase. For example, an aging U.S. population will require urological equipment such as catheters, and demand for personal self-diagnostic devices is also on the rise. These and other ambulatory healthcare facilities can benefit from LSR's hygienic and hypoallergenic qualities, as well as its easy cleaning and disinfection properties.

LSR is increasingly used as a seal in polycarbonate CPAP masks used to treat sleep apnea. The material is tightly sealed, comfortable to wear, easy to clean and even disinfect, and can inhibit the growth of microorganisms. LSRs are also playing an increasing role in the development of needle-free valves to help reduce the number of needles needed in therapeutic settings.

In Conclusion

Increased demand, improvements in molding technology to apply LSR to a wider range of devices, and more molders proficient in using LSR will lead to the widespread use of LSR in medical devices used in clinical and home settings. The availability of this medical material, coupled with expanding interest in and development of new applications, bodes well for LSR.